- #Gecko driver board drivers#

- #Gecko driver board driver#

- #Gecko driver board full#

- #Gecko driver board series#

* Each motor (including master and slave motors) will typically have a home switch for 1 input each (the slave motor has a home switch so the gantry can auto square during the homing process).

#Gecko driver board drivers#

4 motor drivers would need 8 output pins.

#Gecko driver board driver#

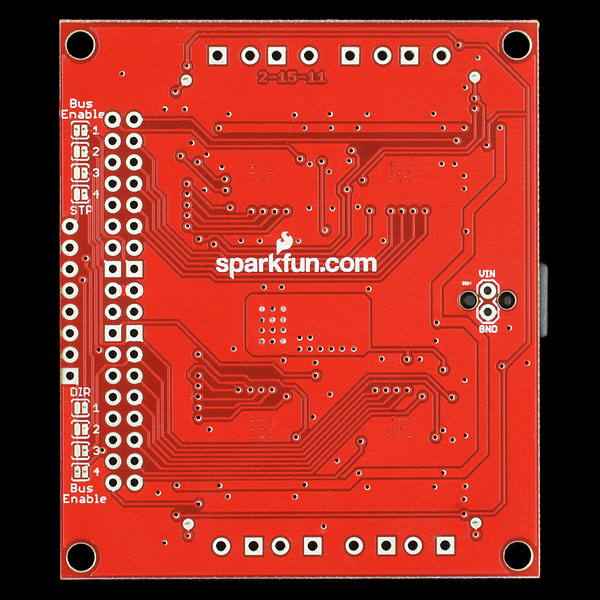

You will need to do your own research to decide what is appropriate for you.Īs you are trying to decide what you will need, here are some common items to consider regarding your hardware needs:ġ) Your EStop (big red switch) should cut power to the motor drivers, but also supply 1 input to the SmoothStepper so the SmoothStepper knows that an EStop event occurred.Ģ) Each motor driver will need 2 output pins, a Step and Dir CW/CCW or Quadrature A & B. Some will work better than others for your needs, and some may not work at all for your needs. This will list all of the commercial BOBs we know of. Please keep in mind that we are not endorsing any particular BOBs, but rather letting you know which ones we know of.

One of the questions we are asked the most, is "Which BOB do you recommend?" Since we don't want to play favorites, we are listing each category alphabetically by manufacturer.

#Gecko driver board series#

In my case, the same four motors wired in series had no problem lifting the same gantry with power to spare. Given how little voltage each motor really needs, you should be able to get five times the power if you use five motors.

#Gecko driver board full#

In contrast, wiring the motors in series splits the voltage, but every motor gets the full current. I found this out the hard way, when I was building a printer where I used four motors to lift a fairly substantial gantry in the vertical direction. If you wire the motors in parallel, every motor gets the full voltage, but the current is split, meaning that the total current is still only 2A - no matter how many motors you add, there is no more power. Pololu Shield is rated 2A and gets 12V from the RAMPS board (or at least I think it does). Using Ohm's Law, such a motor needs 2.2V of power.

RepRap motors are often rated 2A and 1.1ohms. To see why, consider the electrical characteristics of the motors and the driver. Either will work, but motors wired in series will produce more power. To connect multiple motors to a single driver, you can wire them either in parallel, or in series. The wires are connected in order 1A, 1B, 2A, 2B. Each circuit has two wires, call them A and B. Each motor is driven via two circuits, call them 1 and 2. This instructable talks about driving multiple bipolar stepper motors (such as used in RepRap 3D printers) from a single driver, such as a Pololu Shield.

0 kommentar(er)

0 kommentar(er)